Ukwazi lenziwa kanjani iphephaKumele wazi ukuthi ukusungule kuphi, kanjani nokuthi ngubani owakusungula nokuthi kwakukuphi ukuguqulwa kwakho eminyakeni edlule. Wonke umklami omuhle kufanele azi kwenziwa ngani indlela okuzobonakala ngayo umsebenzi wabo.

Kwasungulwa eChina nguHan Hsin ekuqaleni kwekhulu lesi-XNUMX BC. Umbono wokuqala kwaba ngukusungula ingubo engabizi kakhulu. UTs'ai Lum ukhumbula ukwenziwa kwe- UHan Hsin futhi ngathola ukuthi ilahlekile kuphela entweni yokubopha imicu yensimbi kanye nokuyivimba ukuthi ingangenwa ngamanzi (lokhu kufezwe ngokubilisa ulwelwe olubiziwe U-Agar Agar nokusebenzisa i-gelatin yakhipha. I- Idokhumenti endala kunazo zonke eSpain uyena "IMosarabic Missal » yangomhla ka-1040-1050, igcinwe eSigodlweni Sezindela saseSilos.

Ukuziphendukela kwemvelo

- 1450 UGutenberg ucela i-Printing Press.

- I-1670 ne-1680 Inqwaba yamaDashi yasungulwa, eklebhula izingubo ezindala futhi icutshungulwe ngayinye ngayinye.

- 1789 ULuis Nicolás Robert- Wasungula umshini owawungenza iziqephu ezinde zephepha ngetheyiphu eqhubekayo.

- 1807 Ukusetshenziswa kwe-kaolin njengokugcwalisa kuyavela.

- 1874 Kwethulwa inqubo ye-bisulfite.

- 1884 Inqubo yeSulphate noma yeKrafft iyavela.

Izinto zokwenziwa kwephepha

Izinto zokusetshenziswa zokwenza iphepha yilezi:

- Izicubu

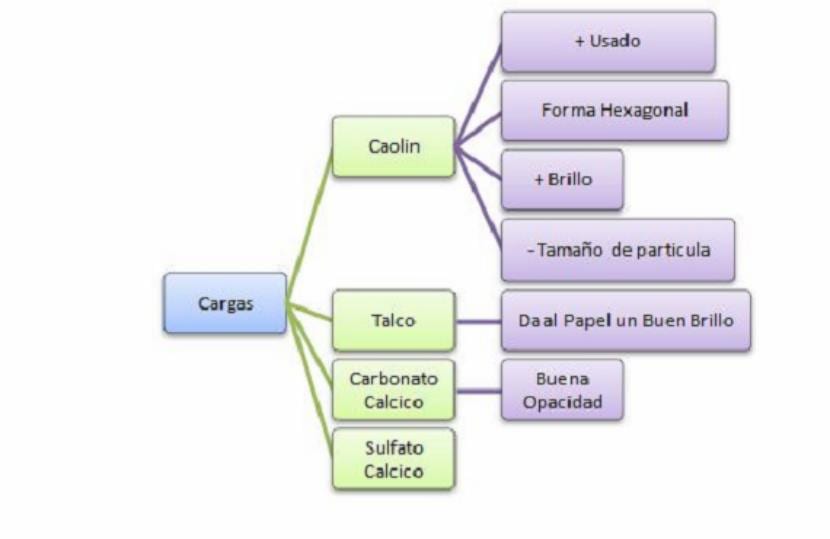

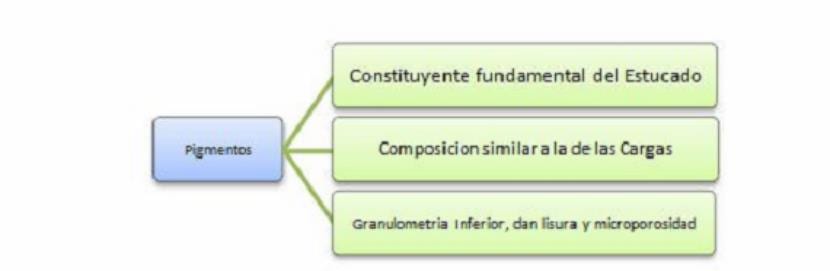

- Ama-filler nezingulube

- Izengezo

Izicubu

- Imicu yezinkuni

- Imicu engeyona yezinkuni

- Imicu yokwenziwa

Imicu yezinkuni

Izihlahla Ezingapheli noma Eziyinhlaka

- Iphayini kuzo zonke izinhlobo zalo kanye nefir

- Ubude obumaphakathi phakathi kuka-2 no-4 mm, noma bude bude

- Ukumelana okuphezulu kwamaphepha wohlelo oluphansi

Izihlahla ezinamanzi noma ezinamaqabunga

- I-Eucalyptus, Beech neBirch

- 1mm ubude obumaphakathi

- Imicu yayo inikeza ubushelelezi nokwakheka okuhle kwephepha

- I-% yayo ephepheni iyanda njengoba uhlelo lolimi lukhuphuka, lukwazi ukufinyelela ku-100% emaphepheni angaphezu kuka-150 gr / m2.

Imicu engeyona yezinkuni

Kungaba yi-bagasse yomoba kanye nama-straw straw, i-hemp, i-esparto, ukotini nefilakisi.

Fibre Ubude:

- Inamanzi ————————-- 4 mm

- Unamahlamvu ————————- 1,5 mm

- I-Bagasse —————————– 1,7 mm

- Ukolweni neBhali —————— 1,5 mm

- I-Esparto ————————— 1,1 mm

- Utshani Nelayisi ———————-- 0,5 mm

- Ukotini ————————––30 mm

Imicu yokwenziwa

- Ukukhiqizwa kwemikhiqizo yezithombe

- Amandla aphezulu ancibilike i-polyethylene

Izinto ezingekho imicu

Imikhiqizo okungaphili okuthi kwesinye isikhathi kube yingxenye yephepha ngobuningi.

Umphumela Wezinkokhelo Nemibala

- Ubumhlophe nokukhanya (i-Refractive Index)

- Ubuningi bayo - imithwalo eyengeziwe, uhlelo lolimi oluningi

- Ukumunca uLiquid - Kuvimbela ukudluliswa kukayinki

- Ukuma kweJiyomethri- Kwenza ukuba khona kunciphise izici zayo zomshini.

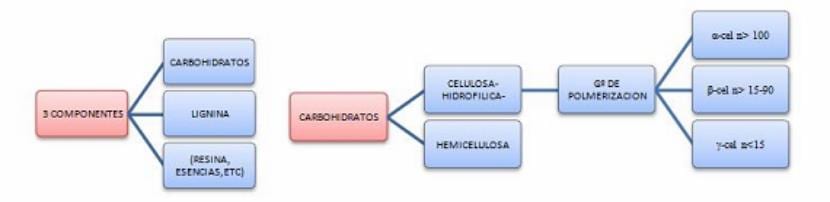

Ukwakhiwa kwamakhemikhali ngokhuni

IHolocellulose: i-cellulose + i-hemicellulose

Lignin: Kuyinto eyinkimbinkimbi kakhulu yamakhemikhali, okuyiyona ebamba imicu ihlanganiswe ngokuqinile.

Mhlophe: Kungumkhanyo obonakalayo wokukhanya.

Eminye imikhiqizo:

| AMA-resino | Lush | |

| I-LIGNIN | I-25 -30% | 18 -30% |

| ICELLULOSE | 40 - 45% | 45 - 50% |

| I-HEMICELLULOSE | 10 -15% | 20 - 30% |

| Izinhlaka | 4% | 1,5 - 2% |

Ukulungiswa kwezinkuni

Kumakiwe

- Kuyadingeka ukuyisusa

- Ayinawo umlingiswa oyindilinga

- Sebenzisa ama-reagents namandla

- Kungcolisa i-pasta

- Isigubhu Esiphakathi Esiphakathi Esikhulu

Isitoreji sezinkuni

- Umswakama ophakathi kuka-25 no-55%

- Phakathi kuka-25 no-35º weThempelesha

- Inamanzi - Akudluli unyaka owodwa

- Leafy - Phakathi kwezinyanga ezimbili nezingu-2 ukugwema ukulahleka kwekhwalithi

Isikiwe

Ngemuva kokumaka izingodo zincishiselwa kuma-chips noma IZINGOZI ukukwazi ukudala ama-pastes athile, afana namakhemikhali, amakhemikhali amancane kanye nokuhlanzwa kwemishini. Usayizi we-chip uzohlobene nokufakwa kwama-reagents asetshenziswe ekuqhumeni.

Ukunamathisela ngomshini

I-pasta ejwayelekile yomshini

- Kusuka ezingodweni zezinkuni ezingasikiwe

- Ngokuvamile inenhlaka

- Ivili lokugaya le-Cylindrical, indawo elicasulayo, elondolozwe njalo.

Amanzi

- Gwema ukushisa

- Hlanza isondo lokugaya

- Ukuhambisa imicu

Izinhlobo ezimbili:

- Iyaqhubeka: UWarren de Cadena

- Dashed: ENyakatho enkulu

Izinzuzo:

- Ukusebenza okuphezulu (95%)

- Izici zesandla esihle (

Okubi:

- Ubunzima bokukhipha umbala

- Ubumhlophe obuphansi <80%

- Ukulimaza udonga lwe-fiber

Ukugoqa noma ukucwenga uginindela womshini:

- Ama-disc shredders, uginindela wekhwalithi ephezulu

- Izici ezingcono zomzimba

Ventajas:

- Ithuba lokusebenzisa izinkuni ezinqatshiwe

- Ithuba lokusebenzisa ukhuni oluqinile

- Unamathela wekhwalithi engafaniyo

Okubi:

- Ukutshalwa kwezimali okuphezulu

- Ukusetshenziswa kwamandla aphakeme

- Izindleko zokugcina eziphakeme

Ukunamathisela kwe-Thermomechanical

- Izici zemishini yokunamathisela kwe-chip ziyathuthukiswa

- Ngalokhu, umusi wethulwa ekushiseni okuphezulu ukushisa ama-chips ngaphambi kokuwangenisa kudiski yokucwenga, okwenza ukuthamba kwe lignin nokunciphisa amandla emicu.

- Ukuthambekela kokuguga bese uphenduka uphuzi

- Ukukhanya okuphezulu. efanelekayo iphepha lesisindo esilula.

Ukunamathisela kwe-Chemical-thermomechanical

- Isivuno esikhulu

- Izimo zomzimba ezingcono kunezinamathiseli ezivamile

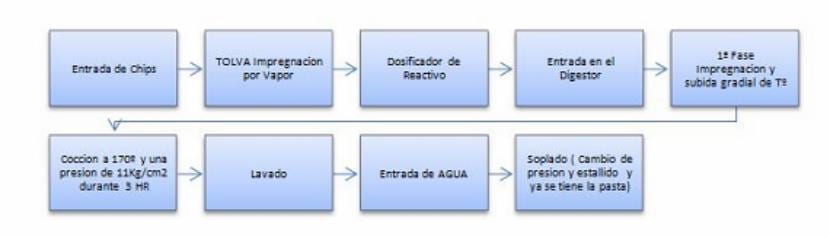

- Ama-chips ancishiswe ngosayizi, bese ku-digester lapho kune-soda ezingeni lokushisa lama-60 kuye ku-80º, amahora amathathu. (Endabeni yokunamathisela kwamakhemikhali, ipheka isikhathi eside nangezinga lokushisa eliphakeme).

Ukunamathisela ngamakhemikhali

- Izinga lokususwa kwe-lignin lizoba likhulu ngokwedlulele ukwelashwa kokudubula kwezinkuni.

2 Izinhlelo:

- I-al bisulfite

- I-Krafft

IBisulfite

- Idalwe eSweden ngo-1874

- Ukupheka utshwala yi-bisulfite ene-calcium, i-magnesium noma i-ammonium base.

- Izinga lokupheka eliphakathi kuka-130º no-140º

- Isikhathi sokupheka phakathi kwamahora ayisithupha kuya kwayisishiyagalombili

- Ukwakhiwa kabusha kulula futhi kuveza ama-pastes acebile ngama-hemicelluloses, afanele amaphepha afana nengilazi.

- Akunakho ukutakula kwamakhemikhali

- Isivuno esiphakathi kuka-45 no-55%

I-Krafft

- Umfutho omkhulu wokufakwa kubhayela lokutakula.

Inqubo yokutakula

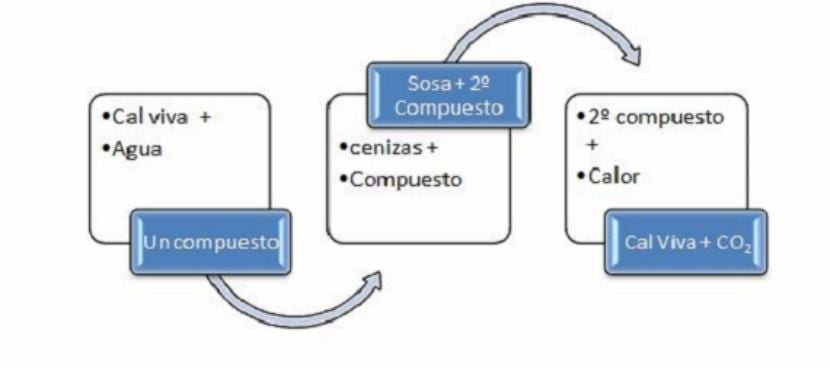

Iziphuzo ezimnyama ezakhiwe ngezinto eziphilayo, amaminerali kanye namanzi ngokuhlushwa kwe-18 kuye ku-20%, yi-evaporator ukuhlushwa kukhushulwa kuma-60%. Kamuva iyashiswa ikhiqiza ukushisa. Umlotha wenziwe nge-sodium carbonate. Ngemuva kwalokho, isoda iyatholakala. Khipha ama-45 kuye kuma-55%.

Mhlophe

Inhloso yokukhipha amakhandlela ukususa i-lignin engasuswanga ngokupheka.

Ukukhipha okuvamile

- Ukuhlobisa

- Isizinda

- I-chlorine dioxide

- Isizinda

- I-chlorine dioxide

- Phakathi kwesigaba ngasinye kunesigaba sokuwasha.

I-Chlorine Dioxide Bleaching

- Ukwehliswa umoya yi-oxygen, bese kuyaphekwa bese kusetshenziswa ukwelashwa nge-chlorine dioxide.

I-Ozone Bleaching

- Ama-degrades + cellulose

- Ubumhlophe obukhulu kunama-90%

- Imiphumela engamukeleki maqondana nokulahleka kokumelana

I-Enzyme Bleaching

- Ama-enzyme namanye ama-bleach

- Ubumhlophe obuphakeme kakhulu

- Ukwehliswa kwe-chlorine dioxide ngo-10-15%

Okwe-oxygen Bleaching

- I-Hydrogen peroxide, esetshenziselwa ukunamathisela kwamakhemikhali nama-thermomechanical

Ukulungisa iphutha

- Ifektri Ehlanganisiwe - Izothunyelwa ngamapayipi.

- Okungadidiyelwe - Ekhathonini, amashidi e-pasta akhiqizwa ngomswakama ka-10% ukwenza lula ukuthuthwa.

- Amanzi amaningi, isikhathi esincane sesikhunta esingaba khona.

Imicu ihlukaniswa

- Imicu Yokuqala

- Imicu yesibili

Imicu eyinhloko

- Zitholakala ngokhuni noma ezinye izinhlobo zezitshalo zemifino, ziyizintambo zokusetshenziswa kokuqala. Izicucu ezivela ezigayweni zamaphepha ezivela kudoti zibhekwa njengemicu eyinhloko.

Isigaxa:

- Yisitsha esine-helix engxenyeni yaso engezansi eshukumisa amashidi e-pasta futhi ahlukanise imicu ngayinye, kulungiswe ukumiswa okunamanzi phakathi kuka-6% no-12% wento eyomile emanzini.

- Izinto zokusebenza zikhishwa ngokudlulisa ingxube nge-grate engavumeli ukudlula kwezingcezu ezinkulu.

- Amanzi asetshenziswa ku-pulper amhlophe, amanzi aphinda asetshenziswe avela efektri uqobo (amhlophe ngenxa yokuqukethwe yimicu nokugcwaliswa).

- I-fiber ende futhi emfushane ibekwa eceleni ku-pulper. Ngeke zixube kuze kube ngemuva kokucwengwa.

Abahlukumezi:

- Zisetshenziselwa ukuxazulula inkinga yezinhlayiya ezingafakwanga kahle ezivela kuginindela. Isabalalisi senziwe ngamadiski amabili afakwe amathini noma ama-projection.

Ukuhlanza:

Ngokucwenga kunikezwa izici zokukhiqiza izinhlobo ezahlukahlukene kakhulu nezigaba zephepha. Iphepha ngalinye lidinga ukucolisiswa okufanele, lezi ezinye izinhlobo:

- Isitaki saseDashi

- I-Angle Conical Refines Encane

- I-Wide Angle Conical Refines

- Ukucwengwa Kwediski

Noma ngabe hlobo luni lokucwengwa, ukusebenza okuyisisekelo kwenziwa phakathi kwento elungisiwe naleyo ejikelezayo, kudluliswa unamathisela phakathi kwabo.

Ngemuva kokucwengwa, imicu ifakwa esenzweni esisebenza ngamandla noma esincanyana esikhiqiza umphumela:

Shake futhi Shake:

- I-fiber ifakwe amanzi

- Hlikihla. I-fiber frays ibe yimicu

- I-Shear- I-fiber ifinyelela ekunciphiseni ubude noma ukusika.

- I-Fibrillation ukukhishwa kwe-fibrils nokukhiqizwa okuhle kakhulu okuholela ekukhuleni okubonakalayo endaweni ethile, kuthuthukise ubude bezinyembezi nokuqhuma kwephepha.

I-fibrillation ephakeme + Ukungazinzi okuphezulu

Umsebenzi wokucwengwa ulawulwa ezingeni lomshini ngomshini olinganisa amandla okususa amanzi noma ijubane elihambisanayo unamathisela avumela ngalo amanzi ukuba akhiphe. Kukalwa kumamaki we-Shopper-Riegler (SRº), inani eliphakeme kakhulu, ukucwengwa kukhulu.

Ukucwengwa okuphezulu = Ukususa amanzi amancane

Ukucwengwa okuncane = Ukususa amanzi amaningi

Uma seyicwengisisiwe, i-pasta igcinwa emavinkini amakhulu ngokuxokozela.

Imicu yesibili

- Imicu esevele inenqubo eyodwa yokukhiqiza ithola leli gama.

- Baziwa ngegama lika IPHEPHA, zingahlanganiswa nezokuqala noma zingaba yi-100% yesibili.

- Izikhungo zokuqoqa zivame ukuba semadolobheni amakhulu futhi uhambo olude oluya ezimbonini lungazenza zingabi nezomnotho.

- Kungenzeka ukuthi uthole ngaphezulu kuka-50%

Isigaxa

- Ngeke nje isebenze njengokwehlukaniswa kwephepha, kodwa futhi izosebenza njengesikhuhli sokuqeda ukungcola okufana nezintambo nezintambo.

- Inqubo ingaqedwa nge-splinter

Kuvaliwe

Yenziwe ngamakhemikhali ngokunengqondo axhumene nokushisa nokusetshenziswa kwamandla wokukhipha i-inki ephepheni.

3 Imikhiqizo:

- Ama-detergents: susa uyinki

- Abahlakazekile: Ukuze uyinki ushiye amanzi futhi ungafaki kabusha.

- Ama-foam agents: Kusiza ukususwa kukayinki.

Inqubo yokuncipha

Kwenziwe ngokugeza

- Kuyinto endala kunayo yonke

- Isebenza kahle isusa izinhlayiya zosayizi we-1 kuye ku-10 we-micron

I-Flotation isuswe inki

- Isetshenziswa kakhulu

- Inhloso yamakhemikhali afakiwe ikhihliza amagwebu nokuthokomala kukayinki.

- Kusebenza kangcono kunokuwasha njengoba kususa izinhlayiya zikayinki ezinkulu futhi ukulahleka kwe-fiber kuncane.

- Udinga amanzi amancane enqubeni

Izinqubo ezihlanganisiwe

- Ukuwasha kusetshenziselwa ukususa izinhlayiya ezincane zikayinki kanye nemithwalo yamaphepha futhi kuthuthukisa inqubo yokulandelana okulandelayo.

Kwenziwe ngama-enzyme

- Umkhuba omusha enqubweni yokwehlisa. Enye yezinkinga kungaba yisizukulwane esiphezulu se-foam.

- Kukhona ukulahleka kwezintambo nokumelana

- Azikwazi ukwenziwa kabusha kabusha unomphela, zivumela ukusetshenziswa oku-3 kuye kwayi-5 kuphela.

Ukwakhiwa kwamashidi

- Kusukela kulo mzuzu kuqhubeke, ukukhiqizwa kufana ncamashi nanoma yiluphi uhlobo lwephepha. Umehluko uzonikezwa ngokwakhiwa nokuphela kwawo.

- Ukwakhiwa Kweshidi: Shintsha ukugeleza kokunamathisela kube yishidi elibanzi nelifana.

Ukuxubha ubhavu

Lapho kunezelwa khona izinto ezihlukile ngohlobo lwephepha njenge:

- Izicubu

- Izibane ezikhanyayo

- Imithwalo

- Izithasiselo eGene

- Sizing ejenti

Ama-debuggers

Izinhlayiya ezingafuneki ziyasuswa.

2 Izinhlobo

Okungenzeka kwenzeke

- Basusa izinhlayiya ezinamandla ngokususelwa ekutheni kungenzeka kangakanani ukuthi badlule esikrinini noma kumesh.

I-Centrifugal

- Basebenzisa amandla we-centrifugal wokujikeleza kwe-pasta ngaphakathi kwezindikimba eziyindilinga ezihlukanisa izinhlayiya ezisindayo, eziphuma ekugcineni okuvulekile okuphansi.

Izinhlelo ezi-2 zivame ukuhlanganiswa ukuze zisebenze kahle kakhulu.

Ibhokisi lekhanda noma ikhanda lomshini

- Isisekelo esiyisisekelo sokwenza amashidi abanzi futhi amancane

- Badinga ukugeleza okungaguquguquki nokufanayo kokungena kwe-pasta.

ezininginingi

- Idivayisi eyenza ingcindezi nokugeleza kokunamathisela kuhlale kububanzi bonke bebhokisi lokungena.

- Igumbi Lokukhulisa: Isiza ukuhlelwa okungcono kwemicu ekumisweni.

Inani lokumiswa noma lokunamathisela elihlanjululwe okufanele lifinyelele endwangwini kumele libe yinto edingekayo:

- Nikeza uhlelo lolimi

- Siza ukuqeqeshwa

- Landelela isivinini sokukhiqiza

- Thola iphrofayili efanayo

Lokhu kulawulwa:

- Ukugeleza (ubuningi)

- Ukungaguquguquki (ukuminyana)

Itafula eliphansi

- 7 noma 8 amamitha ububanzi

- Isiza ukususa amanzi ngokususa amanzi

- Indwangu inomnyakazo onqamulelayo obizwa ngokuthi tracheo, ukuqondisa imicu nokugwema ukubola.

- Umshini Womshini: Ukuqondiswa Kwe-Fibre

- Ukuqondisa okuguqukayo: Ngokumelene nefayibha

- Imishini Emidala: isivinini esiphakathi kuka-30 - 40 m / min

- Lokho kweminyaka emi-4 noma emi-5 eyedlule: isivinini esiphakathi kuka-800 - 900 m / min

- Njengamanje: Isivinini esiphakathi kuka-1300 - 1400 m / min (lokhu akunakuthungathwa)

Izinhlobo ezimbili zethebula

Okuvamile:

- Indwangu eseceleni: Ingxenye yephepha eliyithintayo. Kubi ngokwengeziwe

- Ubuso obuzwayo: Ubuso obuphezulu. Bushelelezi ngaphezulu kwe-% yemithwalo

Indwangu ephindwe kabili:

- Ivumela ukuqondisa ukususwa kwamanzi kuye phezulu ngamabhokisi okudonsa, ukuthola amashidi amaningi ahambisanayo. Isivinini esivela ku-1400 - 1500 m / min

I-Tela

- Kufanele ivumele ukusatshalaliswa okuhle kokunamathisela

- Ukukhipha amanzi

- Vimbela ukudlula kwemicu

- Vimbela imicu ekunamatheleni kuyo

- Ukugeza okulula

- Izinhlobo ezimbili:

- Plastics: + intengo + ukuqina

- Ukudonswa kwamanzi: ukuqedwa kwamanzi

Ama-roller okususa amanzi

- Basekela indwangu futhi basuse amanzi. Ayisetshenziswa lapho umshini weqa ama-300 m / min

Izindandatho

- Ziyizinto ezakhiwe ngemigoqo engazungezi futhi indwangu islayida kuzo.

- Zihlala isikhathi eside futhi ziyaqhubeka ngokwengeziwe.

- Yinto evame kakhulu endaweni yokuqala yokuhambisa amanzi.

Amabhokisi afisayo

- Isenzo esinamandla ngokwengeziwe

- Igebe iyaqhubeka

- Cha amabhokisi ancike ebude bomshini

- Isebenza ngamaphampu we-vacuum.

Silinda yokudonsa

- Into yokugcina yokuhambisa amanzi etafuleni

- Ukuxhumana kwendwangu kugobile futhi kunendawo encane ebusweni

- Inejackethi yensimbi enezingubo ezijikeleza ngejubane lendwangu

Igwebu killer noma roller dandy

- Kuphathwa kuphela ngamatafula ajwayelekile

- Isiza ukufeza blade ebushelelezi neyunifomu

- Ungenza ama-watermark

- I-Headbox —————- 99% Amanzi ———————-- 1% Indaba Eyi-Fibrous

- Indwangu Yokugcina ——————- 80% Amanzi ——————– 20% Indaba Eyinhlekelele

Imishini yokunyathelisa

- Ukucindezelwa okumanzi kwephepha lephepha kwenziwa ngokuthintana nokuzizwa

- Kungasuka ku-80% kuye ku-60% umswakama

Uma ifunwa

- Susa amanzi asalayo ngokushisa

- Izingxenye ezimbili: owomile wokuqala no-1 owomile

- Phakathi kwabo kubekwa uhlelo lokunikeza ukwelashwa okuphezulu ephepheni

- Izinga lokushisa likhuphuka kancane lisuka ku-70º liye ku-120 - 130º

- Imicu iyancipha ngokulandelana kwama-20% ububanzi no-1% - 2% ubude. Lokhu kudala ukungezwani kwangaphakathi.

- Ekupheleni kokulandelana kwe-2 ama-roller ayaqabula

Ukwelashwa komhlaba

Zingaba eziningana:

- Usayizi-cindezela (okwamanje kakhulu)

- Isango - Roll

- UMthethosivivinywa - uBlade

Cindezela usayizi

Kuyinto elula kunazo zonke

Kuqukethe ukufaka ungqimba oluncane lwe-binder.

- Uma kuyi-binder kuphela = i-Offset Paper

- Uma kuyi-binder + pigment = Iphepha elenziwe ngombala

Inani

- Iphepha le-Offset = 1 - 2 gr / m2

- Iphepha elenziwe ngesikhumba = 4 - 5 gr / m2

Thuthukisa ukuphrinta

Kwesinye isikhathi umshini wokucindezela usayizi ufakwa ngaphambili

Isango-roll

- I-sauce idluliselwa kuma-rollers we-applicator ngokusebenzisa i-roller ephakathi

- Ikuvumela ukuthi usebenzise inani elingaphezulu lesendlalelo

- Imvamisa isetshenziselwa amaphepha afakwe emshinini

- Isendlalelo sokukhanya esingu-8 - 10 gr / m2 ngobuso obunye

I-Bill-blade

- Isistimu esetshenziselwa ukumboza umshini

- Isicelo senziwa ohlangothini olulodwa ngensingo ngakolunye nge-roller.

Lisas

- Umshini wakhiwe ngamasondo wensimbi (kusuka ku-2 kuye ku-5)

- Umsebenzi wawo ukushelela iphepha nokulawula ukushuba kububanzi bephepha.

- Azikhanyi

- Imvamisa zilandela amasondo wokupholisa

- Umphumela walo uncike kwingcindezi kanye nenombolo yamaphasi ephepha ngokusebenzisa imigqa yokuxhumana noma AMANIPI.

Pope

Lapho iphepha selidlulile ebushelelezi, lisongwe ngomshini obizwa ngokuthi upapa, lapho-ke lingalandela izindlela ezimbili

- Iphepha Elihlanganisiwe noma Eliboshwe Ngomshini ———--> Liqeda

- Uma liphepha eliphuma emshinini, liya emshinini wokumboza

Iziphuzo ezithunyelwa ekhanda le-coater ziyahlolwa ukuze kuqedwe ukungcola.

Coater

- Umshini osebenzisa isosi le-stucco ekusekeleni

Isigaxa esiboshwe

- Kuyinto evame kakhulu

- Isetshenziswa nge-roller futhi iyalinganiswa futhi idosiwe ngensimbi

- 2 izinhlobo izindwani: Ngesandla Esiqinile (90º wotho) noma Nezimo (45º onqenqemeni ngokwedlulele)

- Okuqinile kunika phakathi kuka-12 - 13 gr / m2 isoso le-stucco

- Ukuguquguquka kunika phakathi kuka-22 - 23 gr / m2 isoso le-stucco

- Bangasebenza ngejubane eliphakathi kuka-600 - 700 m / min. yize manje kunemishini esebenza ku-1200 m / min.

- Ubushelelezi bephepha buzoba buncane ubushelelezi bephepha.

Camera lip blower

- Uketshezi oluningi lufakwa nge-roller esuswa ngumoya ocindezelweyo

- Phakathi kuka-20 kuya ku-40 gr / m2

- Ayikho ngaphezu kwama-350 m / min

- Isosi le-viscosity ephansi

- Kuphelele kancane kunokusula

Ukulungiselela izinto zokumboza,

- Ithangi lokupheka

- Isikhuthazi sokuhlakaza nokwenza homogenize izingxenye zenhlama

- Izihlungi zokususa iphutha

- Imali ebekiwe

- Amaphampu wokudlulisa i-stucco

Ukuhlanganiswa kwezingxenye

Mayelana Nezingulube:

- Ukuhlanganisa

- Ama-Defoamers

Izithasiselo ezinjenge:

- Imibala

- Ama-microbicides

- Izinto zokugcoba

- Ama-Optical Brighteners

- Izinhlaka zokumelana

High isicwebezelisi enamathela

- Eyaziwa ngokuthi i-Cast Camera

- Amalungelo obunikazi amabili:

Uhlelo lweWarren

- Ukusetshenziswa kwe-stucco nge-blower lip

- Kusho ukuba nokusekelwa okushelelayo

- Faka isicelo se-stucco——> Isomiso se-chrome sangaphambi kokuma (infrared) ——-> 180 °

- Inesimo njengoba iphuma yomile kakhulu kwisilinda ye-chrome

Uhlelo lweChampion

- Isicelo seStucco ——–> 80 ° chilli cylinder

- Lolu hlobo lwe-stucco ezimweni zombili lwenziwa ohlangothini olulodwa kuphela. Uma ufuna kokubili, kwenziwa ngokuqhathanisa okubili ngobuso obubodwa.

ISIQEPHU ESIBALULEKILE

ukutadisha iphepha le-fiber kuzoba umphelelisi